What Are You Looking For?

What Are You Looking For?

In 2013, Pharma United successfully became a key subcontractor for the recombinant human insulin API production line of Tianmai Biotechnology with its breakthrough and innovation in the field of sheet technology. As a close collaborator of the general contractor Biopharmax, Pharma United not only provided new solutions for the sheets, doors, windows and ceilings inside the clean room, but also realized the domestic substitution of HPL in the construction of the clean room . Tianmai Biotechnology's subsequent second and third phase project construction still selected Pharma United 's HPL . It is worth mentioning that this cooperation not only deepened the trust and cooperation between Pharma United and Biopharmax, but also prompted Pharma United to become an agent in the Israeli market.

Case Background

In 2013, the domestic production of insulin APIs faced the challenge of low purity . In order to improve the overall level of insulin production in China, Hefei Tianmai Biotechnology Development Co., Ltd. decided to introduce Israel's advanced insulin API production technology to build a high-purity recombinant human insulin API production line .

As the core area of the project, clean room construction has high requirements for the antibacterial properties, disinfection resistance, environmental protection, and ease of construction of the panels used . After in-depth research and comparison, Tianmai Biotech proactively selected the world's leading HPL as the preferred material for clean room construction.

However, at the beginning of the cooperation, the general contractor Biopharmax had some reservations about the technical strength of Pharma United and initially selected the HPL of an internationally advanced friendly company. In the environment where the domestic HPL technology is not yet mature, how to actively develop and improve the new technology of HPL , realize the domestic substitution of HPL , and win the trust of Biopharmax, is a challenge for the clean room construction of Pharma United.

Solution

As a key subcontractor of the project, Pharma United fully considered Tianmai Bio's project demands and lead time. Relying on its deep accumulation and continuous innovation in the field of panel technology, it quickly overcame technical difficulties, optimized the production and application technology of HPL, and provided Tianmai Bio with new panels, doors, windows and ceiling solutions that meet EU GMP standards.

While ensuring that the performance of the panels is not inferior to that of international brands, United Pharma has achieved domestic substitution of HPL at a lower cost - only 60% of the budget of HPL panels of international advanced competitors . In the subsequent second and third phase project construction, Tianmai Bio continued to choose to cooperate with Pharma United.

Finally, with the support of Pharma United, Tianmai Biotech's high-purity recombinant human insulin API production line was quickly built and high-purity insulin crystals were obtained. The entire project construction period was shortened from the expected 19 months to 16 months, which is 16% shorter than the traditional clean room construction period! This cooperation also deepened the trust and cooperation between Pharma United and Biopharmax, and prompted Pharma United to become the agent of the Israel market.

The HPL developed jointly with Pharma has shown unique advantages in this project with its resistance to disinfection, surface antibacterial, antibacterial, anti-collision, anti-scratch, resistance to iodine, acid and alkali resistance, and no rust .

Unlike metal sheets such as color-coated steel sheets, non-metal sheets such as HPL can perfectly adapt to various disinfection environments such as hydrogen peroxide (H2O2 ) disinfection and surface alcohol wiping disinfection. Once a metal sheet is scratched , it will continue to rust from the scratched area and the surface coating will peel off; however, HPL has better surface strength and will not rust even if scratched, ensuring long-term durability and quality standards.

△HPL has no change in the 3% concentration of hydrogen peroxide ( H 2 O 2 ) test, while the metal sandwich panel can be seen to change color

It is worth noting that when Pharma United revisited the clean room ten years later , it was still in like-new condition.

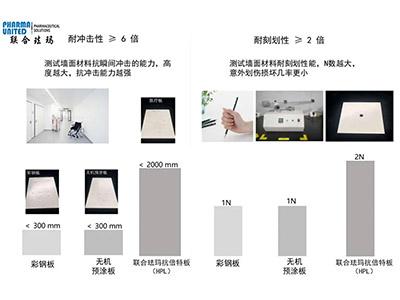

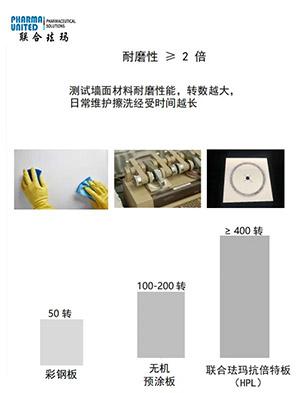

In addition, under the test, the Pharma United HPL has excellent performance in impact resistance, scratch resistance, wear resistance, etc. Compared with metal sandwich panel and inorganic pre-coated panel , the Pharma United HPL has an impact resistance of ≥6 times, scratch resistance of ≥2 times, and wear resistance of ≥2 times.

Tags: hospital cleanrooms, lab wall panels, cleanroom lab walls, sandwich wall panel hospital, cleanroom hospital