What Are You Looking For?

What Are You Looking For?

Cleanroom/laboratory modular design is becoming a buzzword in the construction industry, which means that the modular cleanroom market is showing a steady growth trend worldwide. With the development of modern industry, especially the increasing demand for clean environment in industries such as semiconductors, medicine and food, the growth of the modular cleanroom market has been driven. At the same time, the development of emerging industries, such as biomedicine, new energy and other fields, has also put forward higher requirements for cleanrooms, providing new growth points for the market.

On the one hand, modular cleanrooms can provide a clean environment that meets regulatory requirements like traditional cleanrooms and are equipped with advanced intelligent systems; on the other hand, they have unique advantages. Unlike traditional cleanrooms, modular cleanrooms can be pre-processed and manufactured in the factory and even debugged. After the products are transported to the site, they only need to be assembled and put into place, and can be used after simple debugging. In addition to not disturbing the normal production of the company, this method also shortens the construction period by about 70% compared to traditional cleanrooms. This allows the company to start production quickly and shorten the time to market. In addition, when there is a new market demand, the company can also quickly transform or expand the existing facilities - this will improve the company's response efficiency to market demand and seize market opportunities.

Cleanrooms/laboratories are an indispensable part of modern industrial production, and their construction process requires rigorous and meticulous work to ensure that the final built space can meet the preset cleanliness standards. The cleanroom/laboratory modular construction process includes key steps such as site survey and preparation, design and material selection, factory production and packaging, on-site construction and installation, equipment commissioning and testing, cleanliness testing, operation and maintenance, and monitoring and improvement.

1. Site survey and preparation

Before starting construction, a detailed site survey must be conducted to understand the actual conditions of the site, including space size, structural layout, environmental conditions, etc. At the same time, according to the survey results, a detailed construction plan and construction plan should be formulated to clarify the construction goals, time nodes and personnel division of labor. In addition, the required construction equipment and materials should be prepared to ensure the smooth progress of the construction process.

2. Design and material selection

Based on the site survey results and construction plan, the clean room design work is carried out. During the design process, the cleanliness requirements, process flow, personnel flow and other factors of the clean room should be fully considered to ensure the rationality and practicality of the design. At the same time, suitable building materials and decorative materials should be selected to meet the cleanliness requirements of the clean room and have good fire resistance, moisture resistance, anti-static and other properties.

3. Factory production and packaging

According to the design plan, each module of the clean room is produced and assembled in the factory. During the production process, processing and assembly must be carried out strictly in accordance with the design requirements to ensure the quality and performance of each module. At the same time, the completed modules are packaged for easy transportation and installation.

4. On-site construction and installation

After the packaged modules are transported to the site, on-site construction and installation will begin. First, the site layout is carried out according to the construction plan, and the modules are installed in the designated locations. Then, the modules are connected and fixed to ensure the structural stability and safety of the entire clean room. During the construction process, care must be taken to protect the surface and internal structure of the module to avoid damage and contamination.

5. Equipment debugging and testing

After the clean room is installed, the equipment is debugged and tested. During the debugging process, the performance and operation of each device need to be checked to ensure that it operates normally and meets the use requirements of the clean room. At the same time, the entire clean room is systematically tested, including airflow distribution test, dust particle test, etc., to verify whether the cleanliness of the clean room meets the preset standards.

6. Cleanliness test

After the system is debugged and tested, a comprehensive cleanliness test is carried out. The clean room is fully sampled and tested with professional equipment to obtain data on various cleanliness indicators. According to the test results, it is judged whether the clean room meets the expected cleanliness standards. If there is any non-compliance, targeted rectification and optimization are required.

7. Operation and maintenance

After the modular clean room is put into use, regular operation and maintenance work is required. This includes daily inspection, cleaning and maintenance, troubleshooting, etc. At the same time, a complete maintenance system and emergency plan need to be established to ensure that the clean room always maintains a good operating state and cleanliness level during use.

8. Monitoring and improvement

During the use of the clean room, various operating data need to be monitored and analyzed in real time. Through data analysis, potential problems and hidden dangers are discovered, and timely measures are taken to improve and optimize. At the same time, the development trend of clean room technology and changes in market demand are constantly tracked, and the clean room is continuously improved and upgraded to meet higher cleanliness requirements and wider application needs.

2. Characteristics of cleanroom modularity

The smallest degree of contamination can cause major quality problems in many industries. For example, if any impurities appear on microchips, space probes and lenses, this may cause defects or terminal equipment failure. To avoid damage, companies tend to outsource the relevant manufacturing and assembly steps of high-quality products to cleanrooms. However, these products are expensive, have limited availability, and cannot prevent contamination caused by transportation. United Pharma Clean System Co., Ltd. has developed a mobile cleanroom system in China, that is, a modular cleanroom. Modular cleanrooms can be flexibly set up to ensure the sterility of products during transportation.

Particle impurities and film contamination incur additional costs in many industries. Industries such as semiconductors, food, automotive, aerospace exploration technology and pharmaceuticals may be affected. If a product is contaminated, it is either rejected or must be cleaned subsequently. If a company cannot rely on the cleanliness of its manufacturing environment, a retrospective analysis is required. Both are time and cost intensive. Not all companies, especially small and medium-sized enterprises, have their own cleanroom. Of course, they can rent one or clean parts externally, but in many cases, this is not economically feasible in the long run. In addition, contamination may still occur during transportation. Today, static cleanrooms can only protect products outside of their four walls. With this in mind, United Pharma has received regular requests from the industry to develop a cost-effective, flexible solution.

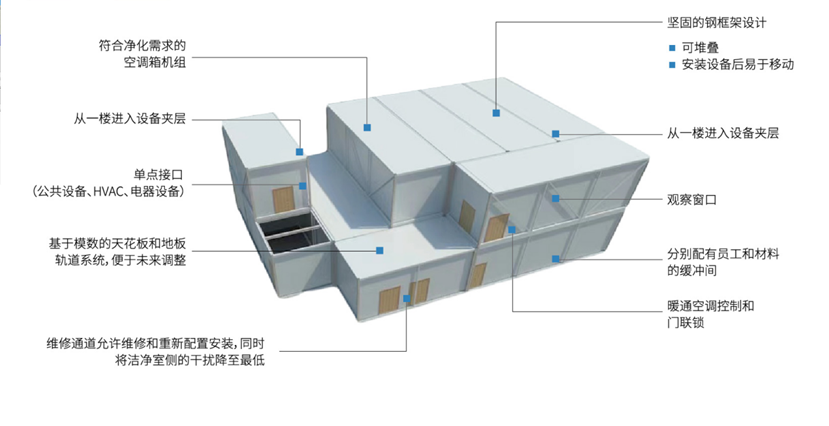

Kunshan-based United Pharma meets these requirements with their "modular" solution. Modular cleanroom systems combine the technical cleanliness standards of cleanrooms with the ability to quickly and simply install and deploy products wherever they are needed. By operating "on demand", companies are not bound by the mandatory occupancy rates of static cleanrooms, which results in significant savings in energy and maintenance costs. Another benefit is that the assembly time is less than an hour. After a short start-up phase, modular cleanrooms are flexible cleanroom solutions that can be used immediately.

The characteristics of modular cleanrooms can be summarized as follows:

1. Efficiency and flexibility

The modular design allows cleanrooms to be quickly built and disassembled, can quickly respond to changes in market demand, and facilitates production line transformation, expansion or relocation.

Due to the modular structure, the scale and configuration of the cleanroom can be quickly adjusted according to actual needs, providing controllable internal purification levels from 1-100K.

2. Cost optimization

The production and installation costs of modular cleanrooms are relatively low because they use prefabricated modules and most of the processing is completed in the factory, reducing on-site workload, construction cycle and cost.

The modular design reduces material waste and increases the material reuse rate, which can reach 98%, which is conducive to enterprise resource integration and optimization.

3. Energy saving and environmental protection

Modular cleanrooms use energy-efficient equipment and materials. For example, dedicated DC motors can save up to 63% energy compared to AC motors, and LED lighting facilities can save up to 50% energy compared to fluorescent lamps. The modular design focuses on sealing and airflow organization, effectively reducing energy consumption, and automatically adjusts air supply through intelligent control systems to reduce unnecessary energy consumption.

4. Intelligent management

The modular cleanroom is equipped with an advanced intelligent control system, which supports 10-inch capacitive touch integrated LCD screen operation, and can monitor and remotely control FFU fans, lamps, etc. in real time. The intelligent system can monitor parameters such as cleanliness, temperature and humidity, pressure difference, wind speed, etc. in real time, and realize automatic fault alarm and location display, so as to facilitate timely discovery and resolution of problems.

5. Easy maintenance and upgrade

The modular design makes daily cleaning and maintenance of the clean room simple and convenient. The double-layer hollow glass enclosure structure does not accumulate dust and is easy to clean. The modular structure facilitates partial replacement or overall upgrade without large-scale demolition and modification, reducing maintenance costs and time.

High cleanliness

Modular clean rooms use purification technologies such as high-efficiency filters, dust-free construction, and airtight sealing to effectively remove harmful substances such as dust, bacteria, and viruses from the air, ensuring that the indoor air quality meets the preset cleanliness standards. By optimizing the design of the interior surface structure of the indoor building and the equipment pipeline, dust accumulation is prevented and pollution sources are reduced.

In summary, modular clean rooms are widely used in electronic optoelectronics, semiconductors, biomedicine, scientific research experiments and other industries due to their high efficiency, flexibility, cost optimization, energy saving and environmental protection, intelligent management, easy maintenance and upgrading, and high cleanliness.

The market is highly competitive and is dominated by some large companies and emerging enterprises. These companies continue to increase their market share through technological innovation and high-quality services, driving the development of the entire industry.

The modular cleanroom industry will continue to maintain a rapid growth trend. With the continuous development of high-tech industries, the requirements for cleanrooms will become higher and higher, and modular cleanrooms will occupy a larger share of the market with their unique advantages. Energy saving and environmental protection will become an important trend in future development. The modular structure, rapid construction, low dust production, low pollution and high recyclability of materials of modular cleanrooms make them more in line with the current mainstream trend of green development.

Pharma United (GMP modular cleanroom manufacturer) offers a range of modular cleanrooms in standard sizes at competitive prices. These cleanrooms can be installed and verified by cleanroom engineers, or you can choose to install them yourself. The company specializes in the rapid production and installation of high-quality customized pharmaceutical, medical and industrial cleanrooms. Our team can design, manufacture and install your certified modular cleanroom on site with minimal interruption in just 6 weeks.

As an advanced clean environment technology, modular cleanrooms are widely used in various scenarios with clean space requirements due to their flexibility, stability and efficiency. With the continuous development of science and technology, modular clean rooms will play an increasingly important role in production, manufacturing and scientific research.