What Are You Looking For?

What Are You Looking For?

The cleanroom HVAC system provides a good operating environment for production equipment by maintaining the cleanliness of indoor air and the stability of temperature and humidity. This helps reduce equipment failures, extend equipment life, and improve production efficiency and product quality. It also provides a comfortable working environment for operators. Through reasonable temperature and humidity adjustment and airflow organization design, the discomfort of operators can be reduced and work efficiency and work quality can be improved.

Item No :

HVAC System Design & EngineeringProduct Origin :

ChinaShipping Port :

ShanghaiPharmaceutical GMP HVAC systems are forced-air systems that provide heating and air conditioning as the air circulates through the system. Duct systems, such as central air conditioning, have a central unit that treats the air, and a blower that circulates treated air throughout a building’s ductwork and into the main living space.

Ductless systems like mini-splits do the same thing, but they exchange air directly with the living space instead of through ductwork. As the air passes through the HVAC unit, it may be run through air filters to remove allergens, dust, or other particles.

With the development of GMP, pharmaceutical GMP certification has been implemented internationally. GMP provides the basic guidelines for pharmaceutical production and quality control. Pharmaceutical production must meet the requirements of GMP, and pharmaceutical quality must meet legal standards. Since the implementation of the pharmaceutical GMP system, it has evolved from the initial GMP to cGMP (current Good Manufacturing Practices) to the international GMP standard announced in 2007 (Pharmaceutical Inspection Convention and Pharmaceutical Inspection Co-operation Scheme, PIC/S GMP , that is, the EU GMP standard), continuously improving the quality and standards of domestic pharmaceuticals.

In order to maintain the cleanliness of the air in the manufacturing process or R&D environment, pharmaceutical factories and laboratories often use dust-free sterile rooms to control air quality. In PIC/S GMP, the clean working environment of sterile pharmaceuticals is divided into four levels: A, B, C, and D. Level A refers to local areas of high-risk operations, such as filling areas, rubber stopper storage basins, open ampoules, and vials. and areas for performing aseptic connections, etc., are usually established in the form of laminar flow workstations. Level B area is the background environment of level A area, and level C and D areas are clean areas that perform less critical stages. The cleanliness standards required for various levels of environments are as follows:

| The maximum allowable amount of particles per cubic meter equal to or larger than the following particle size | Recommended average limits for microbial contamination | |||||||

| Static | Dynamic | Air sample |

Colonization Petri dish (diameter 90mm) |

Colonization Petri dish (diameter 55mm) | Glove fingerprints | |||

| Level | 0.5 µm | 5 µm | 0.5 µm | 5 µm | cfu/m³ | cfu/4hr | cfu/petri dish | cfu/gloves |

| A | 3520 | 20 | 3520 | 20 | <1 | <1 | <1 | <1 |

| B | 3520 | 29 | 35200 | 2900 | 10 | 5 | 5 | 6 |

| C | 352000 | 2900 | 3520000 | 29000 | 100 | 50 | 25 | / |

| D | 3520000 | 29000 | / | / | 200 | 100 | 50 | / |

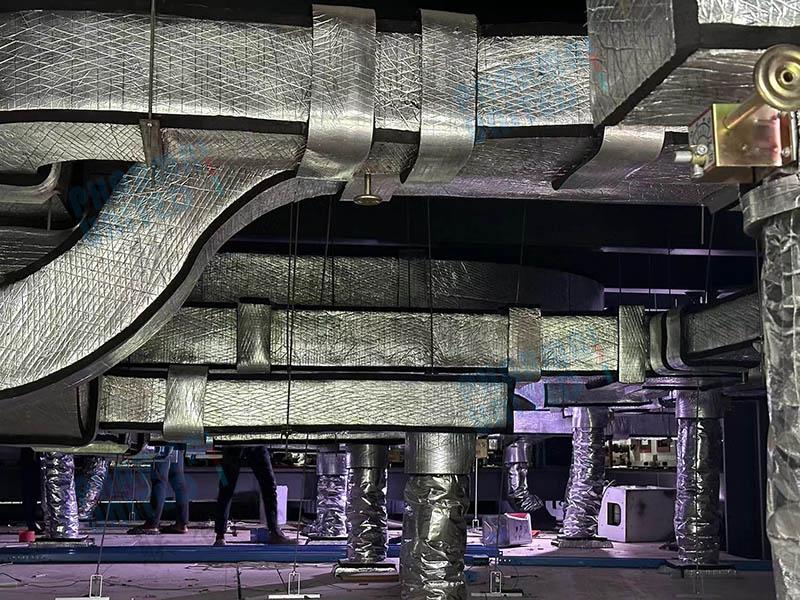

Project photos:

Tags: HVAC engineering, HVAC turnkey supplier, Cleanroom HVAC project

Tags :